If there are higher thermal conductivity, mechanical properties, electrical properties, and other special performance requirements, copper, stainless steel, iron, or silicon steel can also be used as the substrate of the circuit board. Available aluminum models are 6061/5052/1060 and so on. Under normal circumstances, considering conditions such as cost and technical performance, aluminum is the best choice. They show electromagnetic shielding and high dielectric strength.Ĭan the aluminum in the aluminum substrate be replaced with other materials? Such as copper, stainless steel, iron, or silicon steel plates? What kind of metal is used as the PCB substrate, in addition to its heat dissipation performance, the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface condition, and cost of the metal substrate must also be considered. They can help to shrink the overall volume of the product and is also a cheaper option. They help to prolong product shelf life and product power density. They are valid for use in circuit design because of their performance in terms of thermal expansion of circuit design. Others: Aluminum PCBs can be used in power device surface mount technology.For example, when heated from 30-140 degrees, their size only changes by 2.5%-3.0%. Dimensional Stability: aluminum PCBs show dimensional Stability and stable size.They work excellently and are durable and reliable. Since aluminum PCBs work well in terms of Thermal dissipation, they do not have severe expansion or contraction issues. The CTE of aluminum (22ppm/C) and copper(18ppm/C)is quite close. There is no serious problem of thermal expansion or contraction: each substance has its coefficient of thermal expansion.For example, Fr4 PCB with a thickness of 1.5mm will have a thermal resistance of 20-22 degrees per watt, while aluminum PCB with a depth of 1.5mm will have a thermal resistance of 1-2 degrees per watt.

It has two types, namely less than 120 degrees or about 250 degrees (high-temperature resistance) It has a protective effect by protecting the aluminum surface from scratches and unnecessary corrosion.

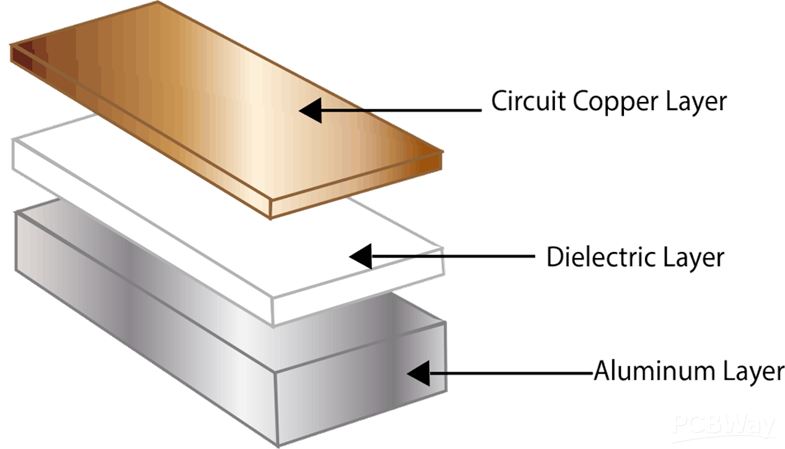

It has excellent thermal conductivity to hold the heat from the components to the aluminum layer. Although this layer is electrically insulated, it can conduct heat efficiently. This layer can be of different materials depending on the temperature range. Dielectric Layer: Aluminum can also conduct electricity therefore, a dielectric material is used between the copper layer and the aluminum layer.It offers the electrical connection and conductivity of current among the components. The layer is common in all types of PCBs, including FR-4. Copper Layer: At the top of the aluminum PCB, there is a copper layer, which creates the circuit.

ALUMINUM PCB HOW TO

0 kommentar(er)

0 kommentar(er)